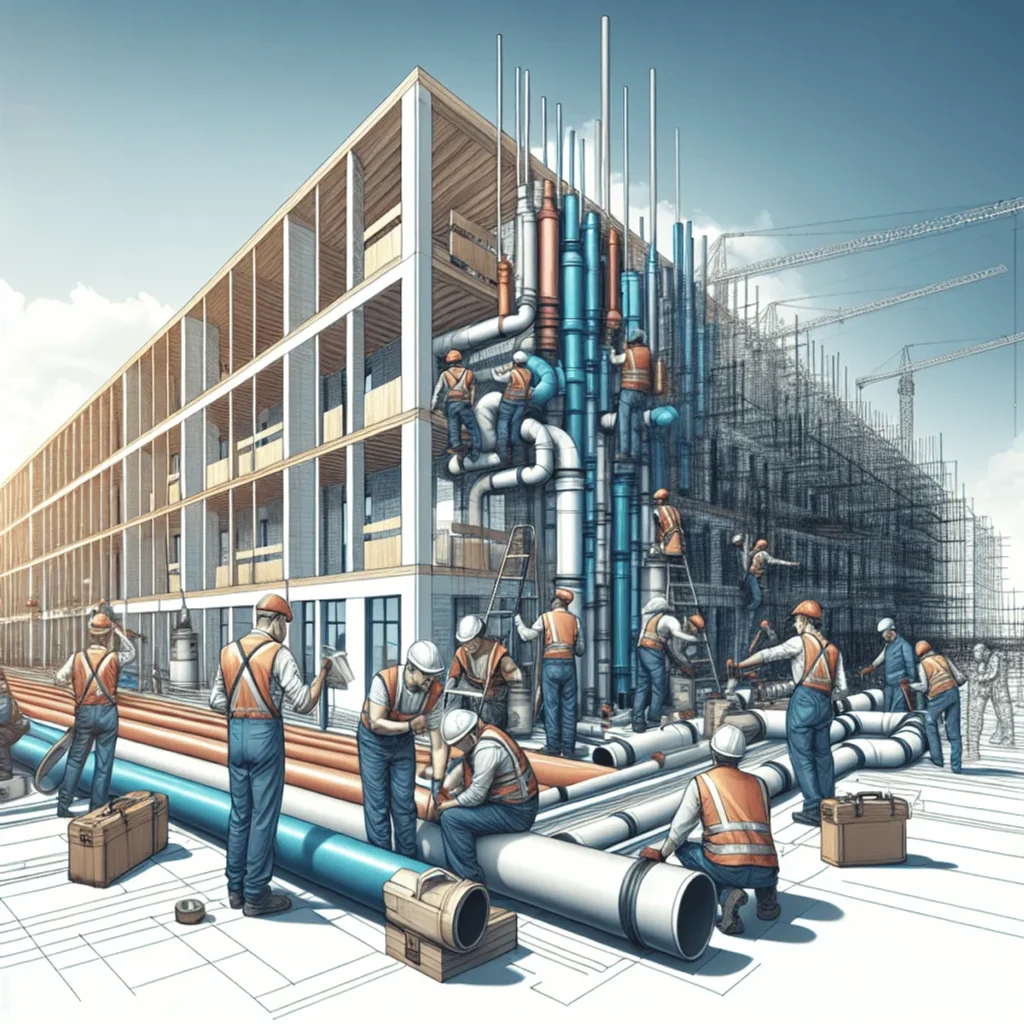

When working in construction and plumbing, it’s important to know the differences between PVC, UPVC, and CPVC. These materials, all made from polyvinyl chloride, have specific qualities suited for different uses.

- PVC (Polyvinyl Chloride): A flexible plastic commonly used in water supply systems, drainage, and electrical conduits.

- UPVC (Unplasticized Polyvinyl Chloride): Strong and long-lasting, often used in window frames, doors, and chemical transport.

- CPVC (Chlorinated Polyvinyl Chloride): Can withstand higher temperatures, making it perfect for hot water distribution and industrial piping.

Knowing these differences helps you pick the right material for your project, ensuring it lasts long, works well, and is safe. Whether you’re dealing with home plumbing or industrial jobs, understanding PVC vs UPVC vs CPVC is essential.

Understanding PVC (Polyvinyl Chloride)

Advantages of Using PVC Pipes

1. Affordability Compared to Metal Pipes

PVC, or Polyvinyl Chloride, stands out as a cost-effective option in plumbing and construction. Its manufacturing process is less expensive than that of metal pipes, translating to lower material costs for your projects. This affordability makes it an attractive choice for both large-scale commercial installations and smaller residential applications.

2. Lightweight Nature for Easy Installation

The lightweight nature of PVC pipes simplifies the installation process significantly. Unlike metal pipes, which require heavy machinery and additional labor for installation, PVC pipes can often be handled manually. This ease of installation not only reduces labor costs but also speeds up project timelines.

3. Durability and Resistance

PVC pipes are known for their durability. They resist corrosion and are unaffected by most chemicals, making them suitable for various environments. Their resistance to oxidation, oil, and ultraviolet light ensures long-term reliability even in outdoor installations.

4. Smooth Surface Reducing Bacterial Growth

The smooth interior surface of PVC pipes minimizes friction, enhancing water flow efficiency. This smoothness also helps in reducing bacterial growth within the pipes, ensuring cleaner water supply systems.

Limitations of PVC Pipes in Hot Water Applications

1. Maximum Temperature Handling (140°F/60°C)

While PVC offers numerous advantages, it has its limitations. One significant drawback is its inability to handle high temperatures. PVC pipes can withstand a maximum temperature of 140°F (60°C). Beyond this threshold, the material becomes susceptible to deformation and potential failure.

2. Limitations in Hot Water Applications Compared to Other Materials

Due to its temperature constraints, PVC is less suitable for hot water applications compared to materials like CPVC or metal pipes. For hot water distribution systems or industrial piping where higher temperatures are standard, alternative materials would be more appropriate.

Understanding these properties and limitations of Polyvinyl Chloride helps you make informed decisions about when and where to use PVC effectively in your projects. Its affordability and ease of installation make it a popular choice for many applications, provided that the temperature requirements align with its capabilities.

Limitations of PVC Pipes in Hot Water Applications

PVC, or Polyvinyl Chloride, is known for its versatility and cost-effectiveness. Despite these advantages, it does have limitations, particularly when it comes to hot water applications.

1. Maximum Temperature Handling

PVC pipes can handle temperatures up to 140°F (60°C). Beyond this point, the structural integrity of the pipe begins to degrade.

2. Heat Tolerance Issues

Unlike CPVC, which can tolerate higher temperatures due to its chlorinated composition, standard PVC lacks the same level of heat resistance.

3. Comparative Limitations

In comparison with UPVC and CPVC, PVC is suited primarily for cold water systems and drainage applications. It falls short in environments requiring high-temperature resistance.

These constraints make PVC less suitable for hot water distribution systems, pushing you to consider alternative materials like CPVC when dealing with higher temperature requirements.

Exploring UPVC (Unplasticized Polyvinyl Chloride)

Applications of UPVC in Construction and Plumbing

UPVC properties make it an ideal choice for construction applications and building projects. Its unplasticized nature results in a more rigid material compared to regular PVC, leading to increased durability and structural integrity.

Use in Construction for Window and Door Frames

- Durability: UPVC’s robust structure ensures long-lasting performance, making it a preferred material for window and door frames. Unlike wood, it does not warp, twist, or split over time.

- Weather Resistance: It withstands harsh weather conditions including UV rays, rain, and wind without deteriorating.

- Maintenance: Requires minimal upkeep as it does not rot or rust. A simple wipe-down keeps it looking new.

- Insulation Properties: Offers excellent thermal insulation, reducing energy costs by keeping interiors warm in winter and cool in summer.

Role in Plumbing for Water Supply Systems

- Chemical Resistance: UPVC is resistant to various chemicals commonly found in water supplies, ensuring longevity and safety.

- Corrosion-Free: Does not corrode like metal pipes, making it suitable for both residential and commercial plumbing systems.

- Ease of Installation: The lightweight nature simplifies the installation process, reducing labor costs and time.

- Smooth Interior Surface: Reduces friction losses during water flow, enhancing the overall efficiency of the plumbing system.

These features underscore the versatility of UPVC in both construction and plumbing contexts. Its use extends beyond just framing and water supply; it’s also applied in ventilation pipes, chemical transport systems, and agricultural irrigation due to its robustness and reliability.

Benefits of Using UPVC over Traditional Materials like Wood

UPVC properties make it a superior choice in various construction applications when compared to traditional materials like wood. This distinction stems from its chemical composition, which lacks plasticizers, resulting in a more rigid and durable material.

Key advantages of UPVC include:

- Durability Against Weather Conditions: UPVC is highly resistant to weather elements, including UV rays, rain, and wind. This makes it particularly suitable for outdoor applications such as window frames and door panels.

- Resistance to Rot and Pests: Unlike wood, which can rot over time and attract pests like termites, UPVC remains unaffected by such issues. This enhances the lifespan of building components and reduces maintenance efforts.

These properties make UPVC a long-lasting material that outperforms wood in durability and resilience, making it an excellent choice for modern building projects.

Understanding CPVC (Chlorinated Polyvinyl Chloride)

CPVC, or Chlorinated Polyvinyl Chloride, is a specialized type of PVC that goes through a chlorination process. This makes it better suited for certain uses. The modification gives CPVC superior temperature resistance and durability, making it perfect for hot water distribution systems and various industrial applications.

Applications of CPVC in Hot Water Distribution Systems and Industrial Piping

CPVC’s enhanced properties make it suitable for several critical applications:

- Use in Both Hot and Cold Potable Water Applications: CPVC is approved for potable water use globally due to its lead-free composition. This makes it an excellent choice for both residential and commercial water supply systems. Its ability to handle temperatures up to 200°F (93°C) ensures reliability in hot water distribution systems, unlike standard PVC which is limited to 140°F (60°C).

- Suitability for Industrial Piping Systems Due to Chemical Resistance: CPVC stands out in industrial environments where chemical resistance is paramount. It withstands corrosive substances that would degrade other materials, making it suitable for transporting chemicals, acids, and other harsh substances. Industries such as pharmaceuticals, food processing, and chemical manufacturing often rely on CPVC piping to maintain safety and efficiency.

Benefits of CPVC Pipes in Construction Projects

The unique properties of CPVC provide several advantages for construction projects:

- Lifespan Exceeding 50 Years with Proper Installation: When installed correctly, CPVC pipes can last over five decades. This longevity reduces the need for frequent replacements, saving time and money on maintenance.

- Need for Specific Bonding Agents Compared to PVC: Installing CPVC requires specific primers and solvent cement designed for its unique chemical structure. These bonding agents ensure secure connections that can withstand high temperatures and pressures without leaking or degrading.

CPVC’s combination of high-temperature resistance, chemical durability, and long lifespan makes it a valuable material in various plumbing and industrial applications. Understanding these features helps in selecting the right type of piping material tailored to specific project needs.

Benefits of CPVC Pipes in Construction Projects

CPVC pipes offer several advantages that make them a preferred choice in various construction applications.

1. Lifespan exceeding 50 years

With proper installation, CPVC pipes can last more than five decades. This longevity is due to their resistance to corrosion and degradation over time.

2. Higher temperature resistance

The process of chlorination enhances the temperature tolerance of CPVC, allowing it to withstand temperatures up to 200°F (93°C). This makes it ideal for hot water distribution systems where other materials might fail.

3. Need for specific bonding agents compared to PVC

CPVC requires unique primers and solvent cement for bonding, ensuring secure and reliable joints. These specialized adhesives contribute to the overall durability and efficiency of the piping system.

The combination of these benefits highlights why CPVC is often chosen over traditional PVC or UPVC in demanding construction projects.

Comparing PVC, UPVC, and CPVC Pipes

Understanding Chemical Resistance

When choosing between PVC, UPVC, and CPVC pipes for your project, it’s essential to understand their chemical resistance. Each type has unique properties that make them suitable for specific environments and applications.

PVC (Polyvinyl Chloride)

- Chemical Resistance: PVC is resistant to many chemicals such as acids, bases, salts, and alcohols. However, it has limitations when exposed to strong oxidizing agents and certain solvents.

- Industries: PVC excels in residential plumbing, drainage systems, electrical conduits, and irrigation. Its affordability and ease of installation make it a popular choice in these areas.

UPVC (Unplasticized Polyvinyl Chloride)

- Chemical Resistance: UPVC possesses excellent resistance to a wide range of chemicals including acids and alkalis. Its rigidity helps maintain structural integrity under chemical exposure.

- Industries: UPVC is commonly found in construction for window frames, doors, and water supply systems. It is also used in chemical transport and ventilation due to its durability against corrosive substances.

CPVC (Chlorinated Polyvinyl Chloride)

- Chemical Resistance: CPVC offers superior resistance to a broader spectrum of chemicals compared to PVC and UPVC. This includes strong acids, alkalis, and various hydrocarbons.

- Industries: CPVC’s enhanced chemical resistance makes it ideal for hot water distribution systems and industrial piping applications. It is extensively used in both residential and commercial settings where higher temperature tolerance is required.

Installation Considerations

Each type of pipe material requires different installation techniques:

1. PVC Installation

- Ease: Lightweight nature facilitates easy handling.

- Tools: Standard cutting tools can be used.

- Bonding: Requires specific solvent cement designed for PVC.

2. uPVC Installation

- Rigidity: More rigid than PVC which may require additional support.

- Cutting: This can be cut with standard tools but may need additional preparation due to its hardness.

- Joining: Uses special adhesives or mechanical fittings suitable for UPVC.

3. CPVC Installation

- Temperature Tolerance: Suitable for higher temperature applications necessitates proper handling.

- Primers & Solvents: Requires distinct primers and solvent cements different from those used for PVC.

- Guidelines: Adherence to manufacturer guidelines ensures long-term reliability.

Understanding these differences ensures you choose the right material based on specific project needs or environmental factors.

Installation Considerations for Each Type of Pipe Material

When comparing PVC, UPVC, and CPVC, the installation process for each material varies based on their specific characteristics:

PVC

- Flexibility: PVC pipes are relatively flexible, making them easier to maneuver during installation.

- Jointing Method: Solvent welding is commonly used. It involves applying a primer and then solvent cement to fuse the pipes.

- Temperature Constraints: Suitable for cold water systems as it cannot withstand temperatures above 140°F (60°C).

UPVC

- Rigidity: UPVC is more rigid due to the absence of plasticizers. This rigidity allows for straight and stable installations but requires precise measurements and cutting.

- Jointing Method: Uses similar solvent welding techniques as PVC but may also involve mechanical joints in certain applications.

- Chemical Resistance: Excellent chemical resistance makes it ideal for both plumbing and construction applications.

CPVC

- Temperature Resistance: CPVC can handle higher temperatures (up to 200°F or 93°C), making it suitable for hot water distribution.

- Jointing Method: Requires specific primers and solvent cements different from those used for PVC. This ensures a strong bond capable of withstanding higher temperatures and pressures.

- Durability: With proper installation, CPVC pipes boast a lifespan exceeding 50 years.

Each material’s unique properties dictate specific installation techniques, highlighting the importance of selecting the right pipe type for your project’s requirements.

Conclusion

Choosing between PVC, UPVC, and CPVC depends on your specific project needs and environmental conditions:

- PVC is great for cold water systems because it’s affordable and easy to install.

- UPVC is perfect for construction projects due to its durability and resistance to rot.

- CPVC is the best option for hot water systems and industrial applications, thanks to its ability to handle high temperatures and resist chemicals.

Make sure to assess your project’s requirements thoroughly before making a decision.

FAQs (Frequently Asked Questions)

What are the main differences between PVC, UPVC, and CPVC?

PVC (Polyvinyl Chloride) is a versatile plastic commonly used for plumbing and drainage applications. UPVC (Unplasticized Polyvinyl Chloride) lacks plasticizers, making it more durable and suitable for construction applications like window frames and door frames. CPVC (Chlorinated Polyvinyl Chloride) has enhanced temperature resistance, allowing it to be used in hot water distribution systems.

What are the advantages of using PVC pipes?

PVC pipes are cost-effective compared to metal pipes, lightweight for easy installation, and versatile for various applications. They are commonly used in cold water systems and drainage due to their chemical resistance.

Why is UPVC preferred over traditional materials like wood?

UPVC offers several benefits over wood, including greater durability against weather conditions, resistance to rot and pests, and better insulation properties. Its lack of plasticizers also contributes to its strength and longevity in construction projects.

What makes CPVC suitable for hot water applications?

CPVC is chlorinated, which enhances its properties, allowing it to handle higher temperatures up to 200°F (93°C). This makes it ideal for both hot and cold potable water applications as well as industrial piping systems requiring chemical resistance.

How do the installation processes differ among PVC, UPVC, and CPVC?

Installation techniques vary for each type of pipe material. PVC requires specific bonding agents and methods suited for cold water applications. UPVC installations focus on structural integrity in construction contexts, while CPVC installations must accommodate its higher temperature handling capabilities.

What factors should be considered when choosing between PVC, UPVC, and CPVC for a project?

When selecting a material for your project needs, consider factors such as the intended application (cold vs. hot water), environmental conditions (exposure to chemicals or weather), durability requirements, and installation techniques appropriate for each type of pipe.

Comments are closed