In maintaining a lush, vibrant landscape, the integrity of our irrigation system plays a pivotal role. Unfortunately, even the most meticulously designed systems are not immune to wear, tear, and the occasional mishap, leading to the need for irrigation pipe repair. A broken pipe can disrupt water distribution, leaving our lawns thirsty and our plants languishing. Recognizing the need for quick and effective repair techniques is essential for any homeowner or gardener. This article aims to demystify the process, offering tangible solutions to ensure your green spaces remain healthy and hydrated.

We delve into an array of subjects, starting with the common causes of pipe breaks, from natural wear and the impact of environmental factors to accidental damage during other garden maintenance activities. Our focus will then shift to various quick repair techniques, covering everything from simple PVC pipe fixes using a hacksaw and flexible pipe solutions to more complex situations requiring specialized pipe fittings or the replacement of sprinkler heads. We also aim to guide you through post-repair tips to prevent future issues, ensuring your irrigation system remains robust. By exploring these topics, we aim to arm you with the knowledge needed for efficient irrigation systems and sprinkler repair, whether you’re tackling lawn irrigation or a more extensive lawn sprinkler repair.

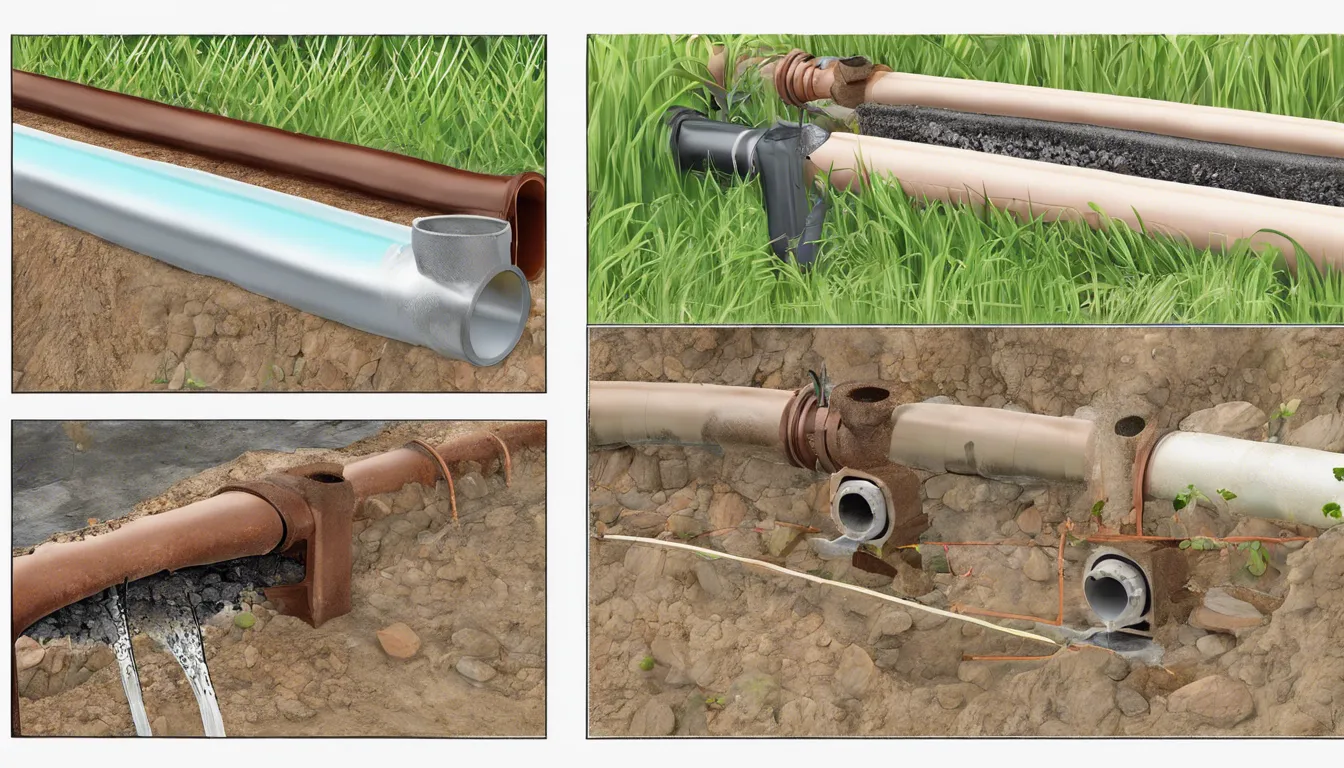

Common Causes of Pipe Breaks

Weather-related damage is a significant factor in pipe breaks. Pipes can burst from the expansion of frozen water inside them, which is why it’s crucial to winterize your irrigation system by draining it before the cold season begins. Additionally, the physical environment, such as heavy clay soils that expand and contract with moisture changes, can exert stress on pipes, leading to fractures over time.

Improper installation also contributes to the frequency of pipe breaks. If PVC pipes are not installed with care, they can be susceptible to damage from too much primer or solvent, which weakens the pipe’s structure. Furthermore, pipes exposed to sunlight for extended periods become brittle due to UV damage, and physical impacts during installation, like dropping or improper handling, can create micro-fractures that develop into larger issues.

Read Also: Understanding Pipes vs Tubes: Dimensions, Applications, and Materials

External factors play a role as well. High-traffic areas increase the risk of physical damage to pipes and sprinkler systems. Vehicles, pedestrians, and even lawnmowers can exert pressure that may cause breaks, particularly at the joints and connections of the irrigation system. Additionally, roots from trees and plants can grow around and exert pressure on pipes, leading to breaks.

By understanding these common causes, we can take preventative measures to maintain the integrity of our irrigation systems and avoid frequent repairs.

Quick Repair Techniques

Using PVC Glue

When repairing irrigation pipes, using the right type of PVC glue is crucial. We recommend a purple primer combined with a blue wet or dry style of cement for optimal chemical bonding, which ensures longevity and durability of the repair. It’s important to apply the primer and glue while the primer is still wet to achieve the best results. This method helps prevent future separations at the joints that could occur years down the line.

Applying Slip Couplings

Slip couplings, also known as repair couplings, are invaluable for quick irrigation pipe repair. These fittings adjust in length, making precise measurements less critical. Begin by turning off the water supply, then mark and cut the damaged pipe section. Attach the slip coupling to the slip fix, apply primer and solvent cement, and secure the connection with a quarter turn to ensure a tight seal. This technique is especially useful for tricky spots where traditional couplings might fail.

Read Also: Finding the Best Drain Cleaner for Kitchen and Bathroom

Utilizing Compression Fittings

For small breaks, a compression sleeve can be a simple yet effective solution. After turning off the water and exposing the broken pipe, clean the area and apply a compression coupling. Ensure the threaded side faces the pipe opening, and secure the nuts without over-tightening to avoid damaging the sleeve. After rechecking for leaks and making necessary adjustments, backfill the excavated area. This method is particularly effective in tight spaces and requires minimal tools.

Post-Repair Tips

Flushing Out Dirt

After we’ve made repairs to our irrigation pipes, it’s crucial to flush out any dirt that may have entered the pipes during the process. I turn on the water supply at the main valve and let the water run through the system for a few minutes. This action helps to clear out debris, ensuring that it doesn’t clog sprinkler heads or drip emitters.

Testing the System

Once the initial flushing is complete, I conduct a thorough testing of the irrigation system. I check each zone individually to ensure that all sprinkler heads and drip emitters are functioning correctly. This step is vital to make sure there are no further leaks or damage.

Monitoring for Leaks

In the days following the repair, I keep a close eye on the repaired sections and the overall system. Monitoring for leaks is essential, as new issues can surface after the system is back in operation. I look for signs of water pooling or unexplained wet areas in the landscape, which could indicate a leak. Regular checks help us catch and address any new problems before they escalate.

Read Also: Home Safety 101: Mastering the Location of Your Water Shut Off Valve

Conclusion

Through the exploration of various irrigation pipe repair techniques and the understanding of common causes of pipe breaks, this article has provided a comprehensive toolkit for maintaining an efficient and healthy irrigation system. From the detailed procedure for using PVC glue, slip couplings, and compression fittings for repairs, to the invaluable post-repair tips aimed at ensuring the long-term functionality of our irrigation systems, we have delved deep into the essentials of effective landscape management. These methodologies not only facilitate quick fixes but also emphasize the importance of prevention and ongoing care.

Reflecting on the broader implications, the knowledge shared here underscores the significance of taking proactive measures to safeguard our irrigation infrastructure, thereby contributing to the sustainability of our cherished landscapes. The guidance provided serves not merely as a solution to immediate repair needs but as a cornerstone for fostering resilience in our gardens and green spaces amid the challenges posed by environmental factors and human activities. Such insights encourage us to remain vigilant and responsive to the delicate balance between nature and the structures we create, promoting a harmonious coexistence that benefits both our environment and our quality of life.

FAQs

1. How can a damaged irrigation line be repaired?

To repair a damaged irrigation line, you can utilize various methods depending on the extent of the damage. These might include using pipe clamps, rubber patches, epoxy putty, or pipe wraps to seal leaks and cracks effectively.

2. What are some methods to fix a leaking pipe without having to replace it?

To fix a leaking pipe without replacing it, consider the following options:

- Use pipe clamps: These are useful for temporarily stopping leaks.

- Employ rubber patches or pipe repair tapes: These can cover small leaks or cracks effectively.

- Apply epoxy putty: This is a durable option for sealing leaks.

- Utilize pipe wraps: These are another effective method for covering and sealing pipe leaks.

3. What is a quick way to repair a leaking pipe joint?

For a quick repair of a leaking pipe joint, epoxy putty is highly recommended. Clean and dry the area around the leak first. Then, mix and apply the epoxy putty around the leaking joint using your fingers or a putty knife to ensure a secure seal.

4. Is PVC glue suitable for use on irrigation pipes?

Yes, PVC glue is suitable and commonly used for securing joints in irrigation pipes. It provides a strong bond under various conditions, including wet, dry, or humid environments. PVC glue ensures that components such as elbows, couplings, adapters, and pipes are well-connected and leak-free.

Comments are closed