PEX plumbing, notably known as cross-linked polyethylene, marks a significant evolution in plumbing technology since its inception in the U.S. during the 80s and 90s, primarily championed for radiant floor heating systems. Distinct for its exceptional flexibility and durability—attributes endowed through the cross-linking of polymer molecules in polyethylene—PEX plumbing presents a robust alternative to traditional copper and galvanized piping.

Given its versatility across various applications, including hot and cold water supply lines to radiant floor systems, PEX plumbing not only simplifies installation but also offers considerable cost savings and efficiency, underscoring why PEX plumbing merits intensive review and analysis [1] [2]. With a lifespan extending up to fifty years, coupled with resistance to corrosion and silent water transport, PEX plumbing encapsulates an innovative solution in the realm of modern construction and remodeling [1].

Understanding PEX Plumbing

Understanding PEX Plumbing involves delving into its core advantages, comparisons with other materials, and its unique properties. Here’s a breakdown:

Advantages of PEX Plumbing:

- Cost-Effectiveness & Efficiency: PEX is cheaper than copper and offers faster installation. It’s resistant to corrosion and less likely to burst if it freezes, making it a durable and reliable option.

- Flexibility & Ease of Use: Its flexibility allows for easy maneuvering around corners, reducing the need for elbow joints. PEX does not require glue for connections, simplifying the installation process, especially in remodeling situations.

- Safety & Durability: PEX keeps harmful chemicals out of plumbing systems as it doesn’t necessitate soldering, solvents, or torches. Manufactured with high-grade materials, it’s designed for longevity and leak-free performance, with many homes enjoying PEX systems for over 30 years.

PEX vs. Other Materials:

- PEX vs. Copper: PEX outshines copper in terms of installation speed, cost, and resilience against freezing.

- PEX vs. CPVC: Costing about the same, PEX wins with its flexibility and no-glue requirement.

- PEX vs. PVC: While PVC is suitable for outdoor use and offers chemical resistance, PEX is preferred for its flexibility, corrosion resistance, and lead-free composition suitable for hot and cold water applications.

Unique Properties of PEX Types:

- PEX-A: Known for its flexibility and crack resistance, even at freezing temperatures.

- PEX-B: Offers chlorine resistance, manufactured through a moisture cure method.

- PEX-C: Provides the best value but is more prone to cracking and kinking due to its manufacturing process involving irradiation.

In summary, PEX plumbing presents a versatile, cost-effective, and durable solution for modern plumbing needs, with various types catering to specific requirements.

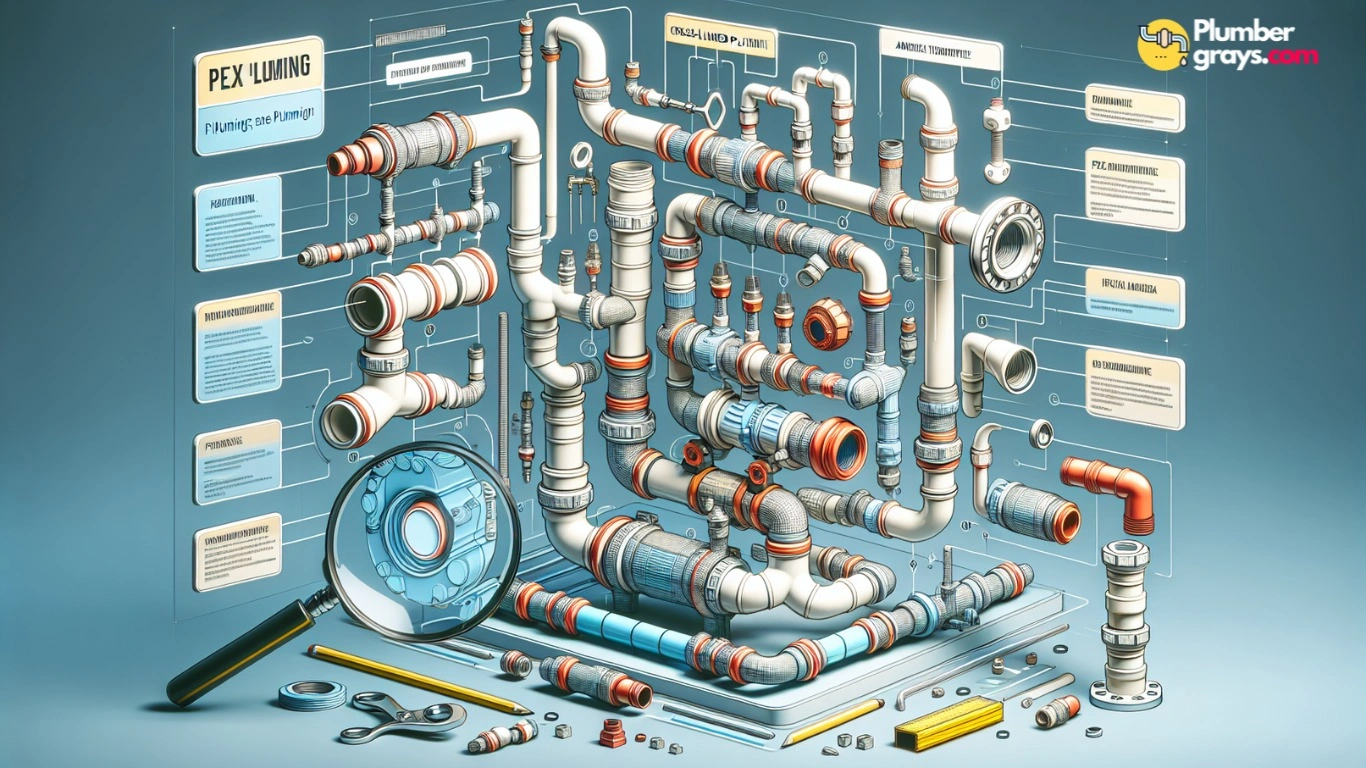

Tools and Materials Needed for PEX Plumbing Installation

Embarking on a PEX plumbing installation project requires a collection of specific tools and materials to ensure a smooth and efficient process. Here’s a breakdown of what you’ll need:

Special Tools for PEX Plumbing:

- Crimping tool or cinch clamp tool: Essential for securing fittings to PEX tubing.

- Scissors-like cutter: For making clean cuts in the PEX tubing.

- Go/no-go gauge: To confirm proper fitting installation.

- Deburring tool: For preparing the copper pipe ends.

- PEX expander tool: Necessary for PEX-A tubing installations.

Materials and Accessories:

- PEX tubing: Available in various colors for hot and cold water lines.

- Fittings: A range of brass or plastic fittings including tees, elbows, couplings, and shutoff valves.

- Crimp rings: Copper or stainless steel options for securing fittings.

- Manifolds: To simplify plumbing runs and minimize potential leaks.

- Stub-outs and valves: For connecting PEX to plumbing fixtures.

Installation Accessories:

- Half clamps: For securing PEX tubing along its route.

- Pressure testing gauge: To ensure the system is leak-free.

- Sharkbite fittings: Ideal for tight spaces, though more costly.

- Insulation: For protecting PEX tubing, especially in colder environments.

Each tool and material plays a crucial role in the installation process, from cutting and connecting the PEX tubing to ensuring a leak-free system. By gathering these items before starting your project, you’ll be well-prepared to tackle PEX plumbing installation confidently and efficiently.

Step-by-Step Guide to Installing PEX Plumbing

Starting with PEX plumbing installation, it’s crucial to understand that its efficiency and lower labor costs come from fewer fixtures and connections. Here’s a step-by-step guide:

- Preparing for Installation:

- For anti-freeze spigots: Drill a hole at a downward angle and run PEX through the wall, securing it with clamps.

- Stub down pipes through the floor before laying the main PEX trunk.

- Use specific bit sizes for drilling: 7/8 inch for 3/4 inch pipe, and 5/8 inch for 1/2 inch pipe, ensuring a slightly upward tilt for garage walls.

- Connecting and Securing PEX:

- Install appliances like ice makers and washing machines by drilling at marked locations and installing PEX to the outlet boxes, securing them with a half-inch crimp ring.

- For fittings, slide a crimp ring onto the PEX, insert a fitting (e.g., a 90-degree elbow), and crimp the ring tightly using a PEX crimping tool. Ensure the crimp ring is no more than 1/4″ from the end of the PEX.

- Testing and Finalizing:

- Pressure test the system with a gauge and shark bite adapter to check for leaks.

- Secure valves inside walls using a 2×10, ensuring they are plumb and level.

- After connecting PEX to fittings with copper crimp rings, verify each connection with a Go/No-Go Gauge.

- Install water hammer arresters and steel protector plates as required, performing a final crimp check before concluding the installation.

This structured approach ensures a thorough and efficient PEX plumbing installation, leveraging its benefits over traditional metal plumbing.

Troubleshooting and Maintenance Tips

In maintaining and troubleshooting PEX plumbing, it’s crucial to adopt a proactive approach to ensure the longevity and efficiency of your plumbing system. Here’s how you can effectively manage and rectify common issues:

Visual Inspections

- Check for Leaks: Regularly inspect visible PEX pipes and fittings for any signs of moisture or drips.

- Assess for Damage: Look out for any physical damage or changes in the PEX material that could compromise its integrity.

- Monitor Fittings and Connections: Ensure all connections remain secure and free from corrosion.

Preventive Measures

- Protect from UV Exposure: Shield PEX pipes from prolonged sunlight to prevent degradation.

- Insulate against Freezing: Wrap pipes in insulation material to guard against freezing temperatures.

- Avoid Excessive Heat: Keep PEX away from high-temperature sources to prevent warping or melting.

Repairing PEX Tubing

- Identifying and Locating Leaks: Use visual inspection, pressure testing, and leak detection tools to pinpoint leaks.

- Minor Leak Repairs: For small issues, cutting the affected section and using a push-fit or compression fitting can be an effective solution.

- Major Leak or Damage Repairs: In cases of significant damage, replacing entire sections of PEX may be necessary. Ensure to use of proper connection techniques to avoid future leaks.

Remember, for complex repairs or if unsure, seeking professional help is advisable to prevent further damage. Regular annual inspections by a professional can also help in identifying potential issues before they escalate.

Conclusion

Throughout this comprehensive analysis of PEX plumbing, we’ve explored its evolution, advantages, and the practical nuances of its installation and maintenance. The attributes that set PEX apart—cost-effectiveness, durability, and flexibility—highlight its superiority over traditional plumbing materials like copper and CPVC. As we’ve seen, whether for new construction or remodeling, PEX plumbing offers a modern solution that aligns with the demands for efficiency and reliability in today’s construction standards, fulfilling a wide array of plumbing needs with its diverse types and applications.

The deployment of PEX plumbing not only signifies a shift towards more innovative construction practices but also elevates the standards of residential and commercial plumbing systems. While considering PEX for your next project, remember the importance of regular maintenance and the proactive troubleshooting tips discussed to ensure the longevity of your plumbing system. The potential of PEX plumbing in revolutionizing the field is immense, promising a future where plumbing systems are more resilient, adaptable, and easier to install and maintain, marking a significant advancement in the construction and remodeling industries.

FAQs

What is the controversy surrounding PEX plumbing?

The controversy with PEX plumbing revolves around two main issues. Firstly, there was a concern about dezincification, which can now be mitigated by specifying low-zinc brass fittings or opting for engineered plastic components. Secondly, PEX was under scrutiny for potentially leaching harmful chemicals such as MBTA, TBA, and BPA, which are considered toxic.

How dependable is PEX A piping?

PEX A piping is regarded as dependable and durable, with an expected lifespan ranging from 25 to 40 years. The lifespan can vary based on the manufacturer and the specific application. Although it may not last as long as copper piping, PEX A is still a widely trusted material in the plumbing industry.

Can you list five potential issues with PEX plumbing?

Certainly, there are a few disadvantages associated with PEX plumbing, including:

- There is a possibility of leaching BPA and other toxic substances.

- PEX is extremely sensitive to UV light, which can degrade the material.

- It can be damaged by certain chemicals and pests.

- PEX is not suitable for installation in areas with high temperatures.

- PEX pipes are semi-permeable, meaning that liquids can potentially penetrate the pipe.

What are the drawbacks of using PEX pipes?

One of the main drawbacks of PEX pipes is their vulnerability to UV light exposure, which can lead to deterioration, particularly in outdoor settings. Additionally, PEX pipes may react with certain chemicals present in the water, raising concerns about the leaching of harmful substances into the water supply.

Comments are closed